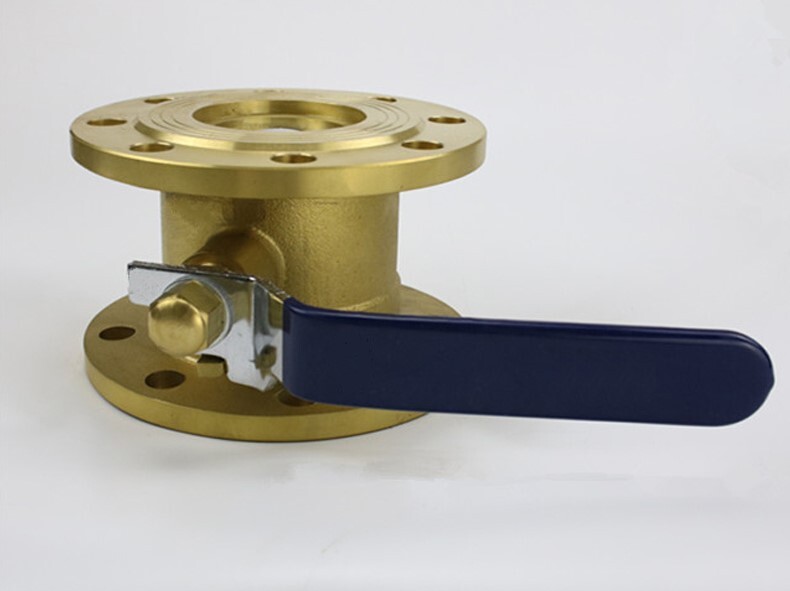

Flanged Brass ball valve

18 USD ($)/Unit

Product Details:

- Material Brass

- Features Corrosion resistant, Full bore, Easy operation, Bubble-tight shutdown

- Control System Manual Lever Handle

- Valve Size Varies, typically DN15 - DN100

- Connection Type Flanged Ends

- Valve Type 2-Piece Flanged

- Voltage Not Required / Manual

- Click to View more

X

Flanged Brass ball valve Price And Quantity

- 18.00 - 25.00 USD ($)/Unit

- 18 USD ($)/Unit

- 10 Piece

Flanged Brass ball valve Product Specifications

- Manual

- Not Required / Manual

- PTFE / Teflon

- Corrosion resistant, Full bore, Easy operation, Bubble-tight shutdown

- Standard, typically 1/2 inch to 4 inch

- Brass

- Flanged Ball Valve

- PN16 / PN25

- Manual Lever Handle

- Industrial, Water, Oil, Gas, HVAC systems

- 2-Piece Flanged

- Flanged Ends

- Water, Oil, Gas, Non-corrosive Fluids

- Varies, typically DN15 - DN100

- -10C to 120C

- Ball Valve

- Brass Machined Ball

Flanged Brass ball valve Trade Information

- Western Union, Letter of Credit (L/C)

- 1000 Piece Per Week

- 15 Days

- Yes

- Free samples are available

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- ISO 9001-2015,CE,FIEO,EEPC

Product Description

- We are engaged in offering304 Stainless Steel Flanged Ball Valve, which is extremely praised in the market. Owing to high demand, professionals make these products in varied patterns.

- Why Choose Our Flanged Brass Ball Valve?

- Engineered for longevity and performance, our ball valve combines robust construction with ease of operation, ensuring years of trouble-free service. Whether you're upgrading existing systems or installing new ones, our valve delivers unmatched reliability and efficiency.

- Invest in quality. Choose [Your Brand] for your flanged brass ball valve needs.

Precision Engineered for Reliability

With durable brass construction and a precision-machined ball, this valve guarantees corrosion resistance and robust performance. Its bubble-tight shutdown ensures zero leakage, making it suitable for critical industrial use. Full bore design allows straight-through flow, reducing pressure drop and supporting a longer operational life.

Easy Maintenance and Serviceability

Routine maintenance is straightforward thanks to low-maintenance design features such as PTFE/Teflon sealing and graphite/PTFE packing. The manual lever handle simplifies operation and servicing, while universal flange mounts enhance compatibility with diverse piping systems across water, oil, gas, and HVAC applications.

Versatile Application and Safety

Built in compliance with international standards, the valve is applicable in various sectors needing reliable fluid control, such as water treatment, oil transport, gas distribution, and HVAC systems. Its manual operation and full-port opening provide efficient flow and safe shutdown, while the wide temperature range enhances versatility.

FAQ's of Flanged Brass ball valve:

Q: How is the flanged brass ball valve installed in industrial piping systems?

A: Installation involves mounting the valve onto system flanges that comply with DIN PN16 standards, aligning face-to-face dimensions per EN558. Universal flange mounts ensure compatibility with most pipe configurations, making the process straightforward for operators and maintenance teams.Q: What applications are suitable for this valve?

A: This brass ball valve is designed for industrial processes involving water, oil, gas, HVAC systems, and non-corrosive fluids. Its robust structure, full port flow, and zero leakage performance make it ideal for both high-demand and safety-critical environments.Q: When should the valve be serviced or maintained?

A: The valve features a low-maintenance design and typically only requires inspection after prolonged use, up to 50,000 cycles. Periodically checking PTFE/Teflon seals and graphite/PTFE packing will ensure sustained leak-free operation and reliable performance.Q: Where can this flanged brass ball valve be used?

A: It can be used in industrial facilities, water treatment plants, oil and gas operations, and HVAC systems. Its universal flange connection and compliance with ISO, DIN, and ANSI standards allow versatile integration into international piping networks.Q: What benefits does the full port design offer?

A: A full port, straight-through design maximizes flow, reduces pressure drops, and facilitates easy cleaning and inspection. This contributes to energy efficiency, consistent performance, and minimal operational disruptions.Q: How does the valve ensure zero leakage?

A: The valve's internal sealing uses high-grade PTFE/Teflon, classified for Class VI zero leakage. Combined with a machined brass ball and graphite/PTFE packing, it provides bubble-tight shutdown for guaranteed safety and environmental protection.Q: What is the process for manual operation of the valve?

A: Manual operation is performed using a steel lever handle coated with PVC for grip and durability. Simply turning the handle rotates the brass ball to open or shut off flow quickly and precisely, supporting fast response in emergency situations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ball Valve' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese