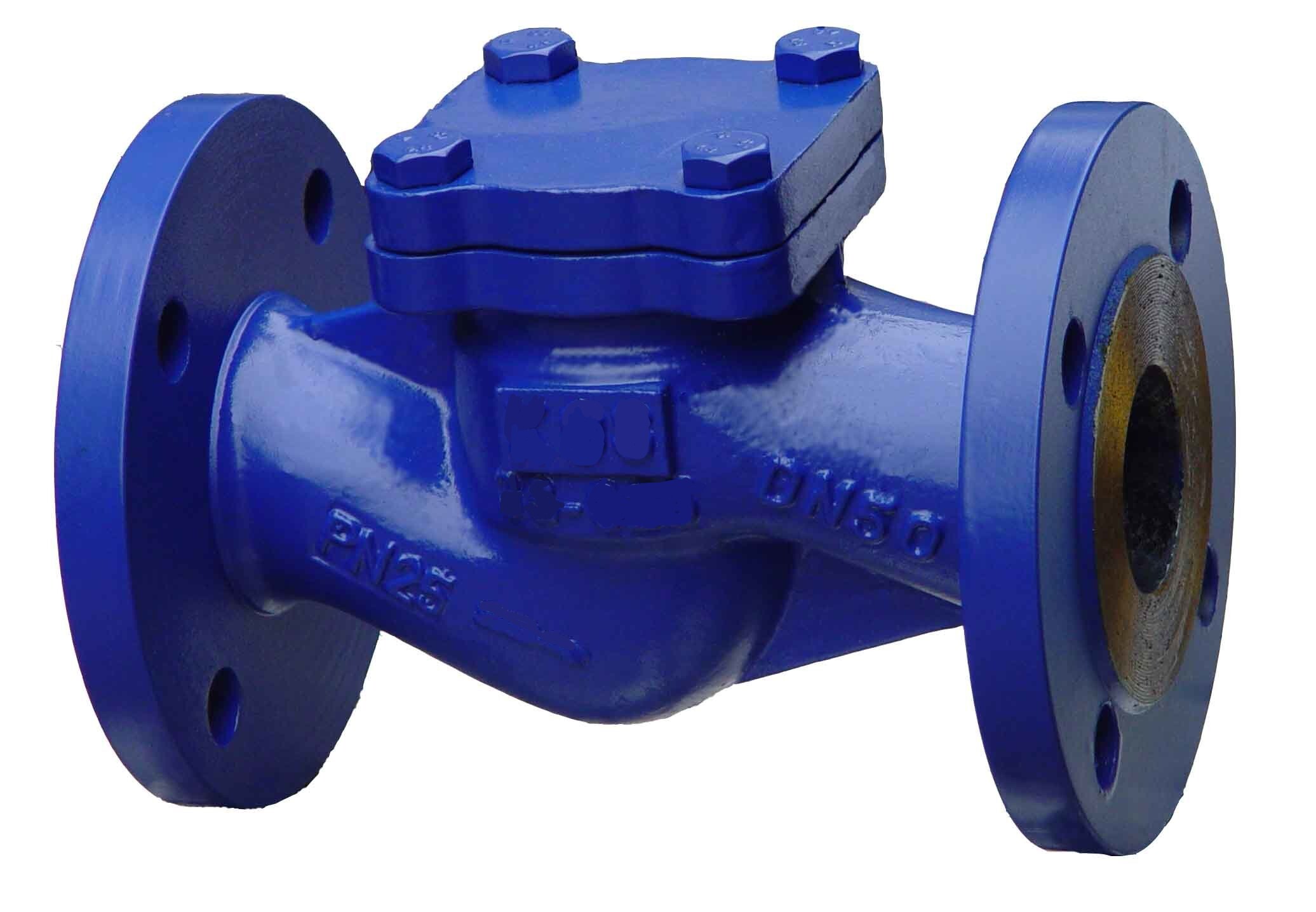

Lift Check Valve

43 USD ($)/Unit

Product Details:

- Valve Size 1/2 to 12

- Control System None/manual

- Material Cast steel, stainless steel, cast iron

- Valve Type Check Valve

- Connection Type Flanged, Screwed

- Features Non-return flow, corrosion resistance, easy maintenance

- Application Industrial fluid control, water, oil, steam pipelines

- Click to View more

X

Lift Check Valve Price And Quantity

- 43 USD ($)/Unit

- 10 Piece

- 43.00 - 50.00 USD ($)/Unit

Lift Check Valve Product Specifications

- Non-return flow, corrosion resistance, easy maintenance

- Lift Type Check Valve

- Water, steam, oil, air, gas

- Hard/soft seated sealing

- Body, bonnet, seat, disc, pin

- Flanged, Screwed

- Cast steel, stainless steel, cast iron

- Stainless steel pivot pin for disc

- Available from inch to 12 inch

- Check Valve

- -10C to 180C

- Up to 16 bar

- Manual / Non-powered

- None/manual

- 1/2 to 12

- Metal disc with lift mechanism

- Industrial fluid control, water, oil, steam pipelines

Lift Check Valve Trade Information

- 1000 Piece Per Week

- 15 Days

- Yes

- Free samples are available

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- ISO 9001-2015,CE,FIEO,EEPC

Product Description

- Features:

- End Connections: Available with various end connections including flanged ends (ANSI, DIN, BS), butt weld ends, threaded ends, or socket weld ends to suit different piping configurations.

- Sealing Mechanism: Utilizes elastomeric seals (e.g., EPDM, NBR, Viton) or metal-to-metal seating to provide a tight seal and prevent leakage.

- Pressure Rating: Designed to withstand a wide range of pressures, typically from ANSI Class 150 to 2500 or PN 10 to PN 420, depending on the valve size and material.

- Applications:

- Industrial Use: Lift check valves are widely used in industries such as oil and gas, petrochemical, water treatment, power generation, HVAC systems, and various process industries.

- Water Systems: Commonly used in water supply systems, wastewater treatment plants, and irrigation systems to prevent reverse flow and maintain system efficiency.

- Steam Systems: Applied in steam lines to prevent backflow which can cause damage to equipment and affect system performance.

- General Purpose: Suitable for applications where preventing backflow is critical to protect equipment, ensure safety, and maintain process continuity.

- Standards and Testing:

- Compliance: Manufactured according to industry standards such as API 6D, API 598, ASME B16.34, DIN 3230, BS 1868, etc., ensuring reliability and performance.

- Testing: Undergoes rigorous testing procedures including pressure testing and leak testing to verify operational efficiency and durability under various conditions.

Reliable Industrial Non-Return Solution

The Lift Check Valve ensures seamless and secure one-way fluid flow, preventing backflow and protecting pipeline systems in industrial applications. With compatibility for water, oil, steam, and gases, it stands as a dependable choice for various sectors requiring consistent performance and safety, especially where the reversal of flow could cause significant issues.

Built for Durability and Longevity

Constructed from high-grade cast steel, stainless steel, or cast iron, and featuring an epoxy or anti-corrosive paint finish, this valve resists wear and corrosion over time. Its robust design allows withstanding demanding conditions, making it fit for harsh industrial environments while ensuring minimal maintenance and an extended service lifespan.

Versatile Design for Easy Integration

Available in port sizes from 12 inch to 12 inch and suitable for installation with flanged or screwed ends, the lift check valve adapts flexibly to diverse pipeline requirements. Its hard or soft-seated sealing and asbestos-free packing make it safe, compliant, and adaptable across a wide range of media and process needs.

FAQ's of Lift Check Valve:

Q: How is the Lift Check Valve installed, and in which position should it be placed?

A: The Lift Check Valve is designed for horizontal installation, ensuring uni-directional flow. Proper alignment and orientation according to the arrow marked on the body are crucial to prevent backflow and maintain system safety.Q: What makes this check valve suitable for corrosion-prone environments?

A: The valve utilizes an epoxy or anti-corrosive paint coating on its body, which, combined with the use of durable materials like cast steel, stainless steel, or cast iron, provides strong resistance against rust and corrosion, making it ideal for harsh environments.Q: When should I use a lift check valve in my industrial pipeline system?

A: A lift check valve should be used wherever backflow prevention is necessary. It's suitable for water, oil, steam, or gas pipelines, especially in systems where fluid reversal could damage equipment or disrupt operations.Q: Where can these lift check valves be applied effectively?

A: These valves are employed extensively in industrial fluid control for water supply networks, oil and steam pipelines, air systems, and gas transmission, serving sectors like manufacturing, power plants, and process industries.Q: What is the process for routine maintenance of this valve?

A: Routine maintenance involves shutting down the line, releasing system pressure, and unbolting the bonnet for internal inspection. With a bolted bonnet and a straightforward design, cleaning, disc checking, and seat inspection are easily accomplished.Q: What benefits does the stainless steel pivot pin add to the valve's function?

A: A stainless steel pivot pin ensures smooth, reliable lifting movement of the disc, contributing to longer operational life, high resistance to corrosion, and consistent sealing performance under frequent use.Q: How does the valve accommodate different pressure and temperature conditions?

A: Designed under API 6D and BS 1868 standards, the lift check valve handles pressures up to 16 bar and operates reliably from -10C to 180C. This makes it versatile for diverse industrial processes and media.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Check Valve' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese