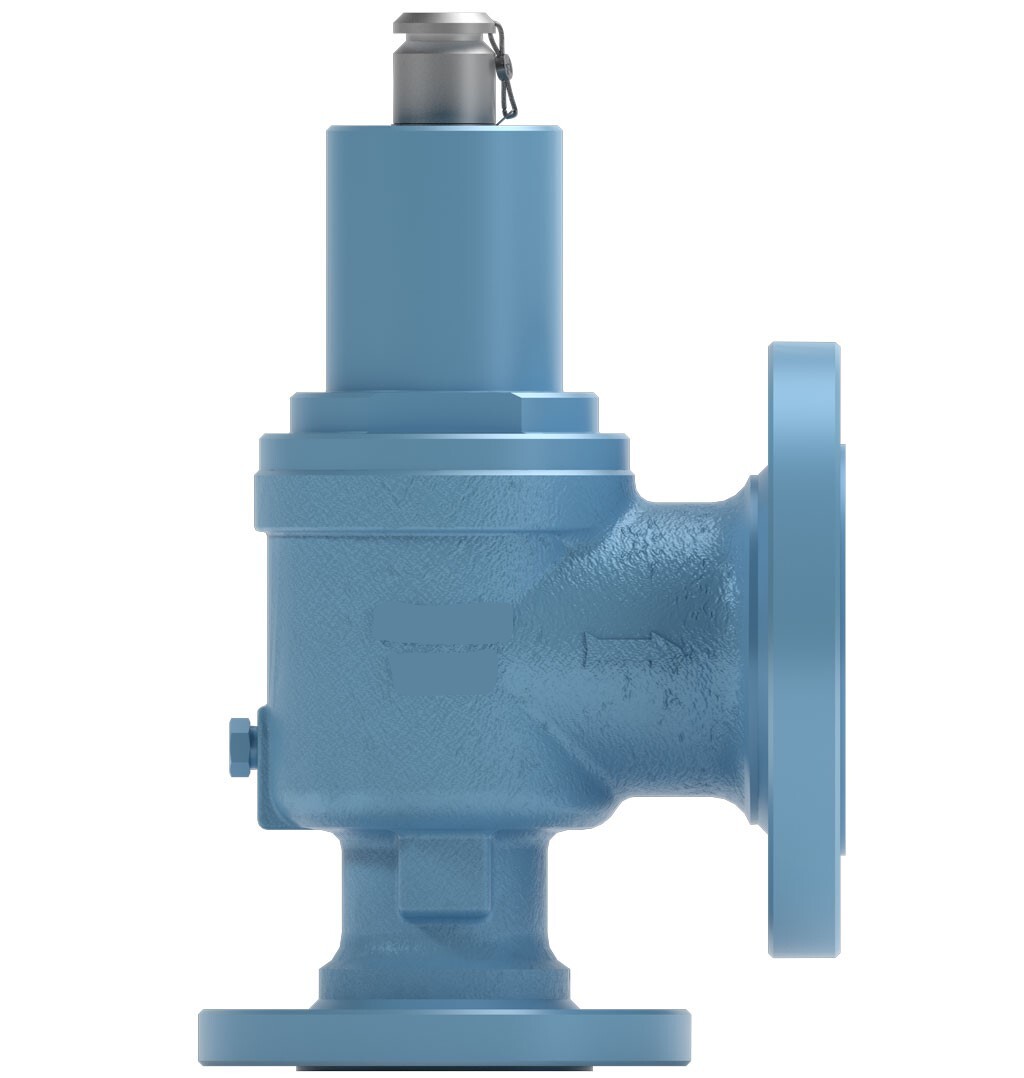

Pilot-Operated Safety Relief Valves

740 USD ($)/Unit

Product Details:

- Valve Size DN15 to DN300

- Features High repeatability, Low maintenance, Precise and stable set pressure, Leak-proof sealing, Corrosion resistant

- Connection Type Flanged, Screwed, Welded Ends

- Material Carbon Steel, Stainless Steel, Cast Steel, Alloy Steel, Custom Alloys

- Valve Type Safety Relief Valve

- Control System Pilot Operated with auxiliary control pilot for pressure setting

- Voltage Not Applicable (Mechanical/Pneumatic control)

- Click to View more

X

Pilot-Operated Safety Relief Valves Price And Quantity

- 740 USD ($)/Unit

- 10 Piece

- 740.00 - 800.00 USD ($)/Unit

- Epoxy Coated / Shot Blasted / Painted

- Vertical (standard), Horizontal on request

- Generally between 0.94 and 0.98

- ASME Section VIII / API 526 / API 520 / ISO 4126

- Manual lifting device, Heater, Limit switch, Exhaust hood

- Up to 500,000 Nm³/hr (depending on size and set pressure)

- Utilizes a pilot valve to control the main relief valve operation for higher accuracy and efficiency

Pilot-Operated Safety Relief Valves Product Specifications

- Manual / Pneumatic Actuated

- Pilot-operated, Spring loaded, Full or Semi Nozzle Type

- High repeatability, Low maintenance, Precise and stable set pressure, Leak-proof sealing, Corrosion resistant

- 1/2 to 12 (DN15 - DN300)

- Carbon Steel, Stainless Steel, Cast Steel, Alloy Steel, Custom Alloys

- Flanged, Screwed, Welded Ends

- Metal to Metal / Soft Seated (PTFE, Viton, etc.)

- Pilot Operated Safety Relief Valve

- Pilot Operated with auxiliary control pilot for pressure setting

- Safety Relief Valve

- Set Pressure Range: 0.5 bar to 400 bar

- Stainless Steel / Alloy Steel / Custom Materials

- Stainless Steel or as per design

- Not Applicable (Mechanical/Pneumatic control)

- DN15 to DN300

- -29C to 427C (Standard), Higher ratings available on request

- Steam, Gas, Air, Vapors, Liquids

- Overpressure protection in pressurized systems, such as boilers, pressure vessels, and pipelines

- Epoxy Coated / Shot Blasted / Painted

- Vertical (standard), Horizontal on request

- Generally between 0.94 and 0.98

- ASME Section VIII / API 526 / API 520 / ISO 4126

- Manual lifting device, Heater, Limit switch, Exhaust hood

- Up to 500,000 Nm³/hr (depending on size and set pressure)

- Utilizes a pilot valve to control the main relief valve operation for higher accuracy and efficiency

Pilot-Operated Safety Relief Valves Trade Information

- Western Union, Letter of Credit (L/C)

- 1000 Piece Per Week

- 15 Week

- Yes

- Free samples are available

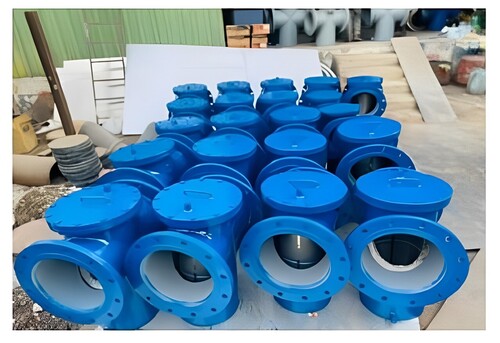

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- ISO 9001-2015,CE,FIEO,EEPC

Product Description

- Pilot-operated valves arepressure relief valves that control the main valve's inlet and outlet port. They are similar to spring-loaded valves but are the best alternative solution for reaching the highest pressure and highest capacity. These valves offer excellent performance for overpressure protection.

Precise Overpressure Protection

These safety relief valves ensure exact set pressure activation, thanks to their pilot-operated, spring-loaded design. With discharge coefficients reaching up to 0.98, they deliver secure, efficient relief, preventing system failures in industrial environments. Each valve undergoes rigorous testing to ASME, API, and ISO standards for performance assurance.

Flexible Mounting and Accessories

Vertical installation is the standard mounting orientation, but horizontal mounting is also available upon request to suit diverse system layouts. Optional accessories like manual lifting devices, heaters, limit switches, and exhaust hoods enhance functionality and adaptability for specific operational needs.

Durable Construction with Versatile Media Compatibility

Manufactured from premium materials including carbon steel, stainless steel, alloy steel, and custom alloys, these valves offer corrosion resistance and compatibility with a wide range of media such as steam, gas, air, vapors, and liquids. Metal-to-metal and soft-seated options further ensure reliable leak-proof sealing under varying pressure and temperature conditions.

FAQ's of Pilot-Operated Safety Relief Valves:

Q: How does a pilot-operated safety relief valve function?

A: A pilot-operated safety relief valve utilizes a smaller, pilot valve to sense system pressure and control the opening of the main relief valve. This mechanism allows for highly accurate pressure control, minimal leakage, and stable operation, making it suitable for critical overpressure protection tasks.Q: What media can be handled by these pilot-operated safety relief valves?

A: These valves are designed for overpressure protection in systems containing steam, gas, air, vapors, or liquids, thanks to their robust construction and versatile sealing materials like PTFE and Viton. Their adaptability ensures safe operation in varied industrial processes.Q: When should I consider using a pilot-operated safety relief valve instead of a direct-acting design?

A: Pilot-operated designs are recommended when higher accuracy, stable set pressure, and low maintenance are needed, or when handling high flow rates (up to 500,000 Nm3/hr) and pressures up to 400 bar. They are ideal for demanding applications in power plants, refineries, and large-scale manufacturing.Q: Where can these safety relief valves be mounted?

A: The standard mounting orientation is vertical, which optimizes valve performance and reliability. However, horizontal mounting is also available upon request to accommodate specific piping arrangements or site requirements.Q: What is the installation process for these valves?

A: Installation involves securing the valve in the preferred orientation, connecting via flanged, screwed, or welded ends, and ensuring all control and auxiliary devices are correctly configured. The choice of port size (DN15-DN300) and connection type depends on system design and operating parameters.Q: What are the main benefits of using this type of safety relief valve?

A: Key benefits include precise pressure control, stable operation, high flow capacity, leak-proof sealing, and excellent corrosion resistance. Their robust construction and optional features support low maintenance and long-term service even in demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Safety Relief Valve' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese