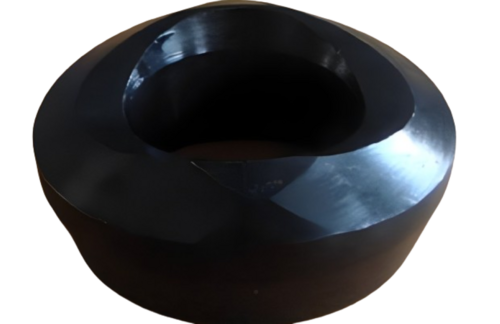

Reducing Elbow 90 degree

9.7 USD ($)/Unit

Product Details:

- Tolerance 0.5 mm

- Diameter Reducing Sizes (Variable)

- Yield Strength Up to 320 MPa

- Bend Radius Short Radius (1D), Long Radius (1.5D)

- Flexibility Rigid Elbow

- Temperature Range -20C to +180C

- Sealing Type No Integrated Sealing

- Click to View more

X

Reducing Elbow 90 degree Price And Quantity

- 10 Piece

- 9.70 - 15.00 USD ($)/Unit

- 9.7 USD ($)/Unit

- Plain, Beveled, Threaded

- 90 Degree Change

- As specified by manufacturer

- RoHS / ISO 9001:2015

- Varies by Size (e.g., 300g to 8kg)

- Box Packing / Wooden Crate

- Excellent in Stainless Steel variants

- 1.5x Rated Pressure

- Manual or Automated Welding/Threading

- Meets ASTM F409 where applicable

- Water, Oil, Air, Steam, Chemicals

Reducing Elbow 90 degree Product Specifications

- Elbow, 90 Degree Angle

- 3 mm to 10 mm

- Plumbing, Industrial Piping, Gas Fitting

- ASTM A234 / ASME B16.9 / DIN / JIS

- Round

- 0.5 mm

- Reducing Sizes (Variable)

- SS304, SS316, MS IS 1239/3589, Brass IS 319

- 1/2 inch to 24 inch

- Welded, Threaded, Socket Weld

- Up to 320 MPa

- Short Radius (1D), Long Radius (1.5D)

- Rigid Elbow

- Stainless Steel / Mild Steel / Brass

- -20C to +180C

- Oil & Gas, Chemical Processing, Water Supply, Power Plants

- Galvanized / Powder Coated / Polished

- No Integrated Sealing

- Standard as per specification / Custom

- Butt Weld, Socket Weld, Threaded

- Reducing Elbow 90 Degree

- Zinc, Epoxy, Custom

- Silver / Grey / Custom

- Up to 580 MPa

- NPT, BSP, BSPT

- Up to 40 bar

- Plain, Beveled, Threaded

- 90 Degree Change

- As specified by manufacturer

- RoHS / ISO 9001:2015

- Varies by Size (e.g., 300g to 8kg)

- Box Packing / Wooden Crate

- Excellent in Stainless Steel variants

- 1.5x Rated Pressure

- Manual or Automated Welding/Threading

- Meets ASTM F409 where applicable

- Water, Oil, Air, Steam, Chemicals

Reducing Elbow 90 degree Trade Information

- Western Union, Letter of Credit (L/C)

- 1000 Piece Per Week

- 15 Days

- Yes

- Free samples are available

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

- ISO 9001-2015,CE,FIEO,EEPC

Product Description

- An elbow pipe is a type of pipe fitting that allows for a change in the direction of the piping system.

- It is designed to facilitate a change in the flow direction of fluids (liquids or gases) within a pipeline.

- Elbow pipes are typically curved and come in various angles, most commonly 90 degrees and 45 degrees, although other angles are also available.

- They are used when a change in the direction of flow is needed, allowing pipes to be connected at different angles instead of in a straight line.

- These fittings are crucial for routing pipelines around obstacles, navigating tight spaces, or simply changing the direction of fluid flow within a system.

- Elbow pipes are available in different materials such as metal (like stainless steel or copper), PVC (polyvinyl chloride), or other plastics, chosen based on the specific requirements of the application and the nature of the substances being transported within the piping system.

Superior Manufacturing for Diverse Applications

Our Reducing Elbow 90 Degree fittings meet stringent global standards, including ASTM and ASME, and are crafted with high-quality stainless steel, mild steel, or brass. Suited for both industrial and plumbing needs, they offer robust performance under pressures up to 40 bar and temperatures from -20C to +180C.

Flexible Options for Seamless Integration

Available in multiple sizes and finishes, these elbows are offered with various end and connection types, making installation straightforward, whether welded or threaded. Each part is thoroughly leak-tested and packed securely to ensure its integrity upon arrival.

FAQ's of Reducing Elbow 90 degree:

Q: How is the Reducing Elbow 90 Degree installed?

A: The elbow can be installed manually or using automated systems, with options for butt weld, socket weld, or threaded connections. Installation method depends on pipe material, system requirements, and selected end type (plain, beveled, threaded).Q: What types of media can pass through these elbows safely?

A: These fittings are suitable for a wide range of fluids, including water, oil, air, steam, and various chemicals, making them ideal for plumbing, industrial piping, and gas fitting applications.Q: When should a reducing elbow be used rather than a standard elbow?

A: Use a reducing elbow when both a 90-degree direction change and a transition between two pipe diameters are needed, streamlining the system and minimizing the need for additional fittings.Q: Where are these reducing elbows commonly used?

A: They are extensively used in oil & gas, chemical processing, water supply, power plants, and general industrial piping where flow redirection and pipe size change are required together.Q: What are the benefits of choosing stainless steel or coated variants?

A: Stainless steel elbows provide excellent corrosion resistance and longevity, while galvanized, powder-coated, or epoxy-coated variants offer additional protection against harsh environments, extending service life.Q: What quality and safety standards do these fittings comply with?

A: The reducing elbows conform to international standards such as ASTM A234, ASME B16.9, DIN, and JIS. They meet RoHS, ISO 9001:2015 requirements, and, where relevant, fire safety standards like ASTM F409.Q: How is product integrity and reliability ensured before shipping?

A: Each fitting undergoes leakage testing at 1.5 times the rated pressure and thorough quality checks for dimensions and surface finish. Products are securely packed in boxes or wooden crates for safe transportation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Fittings' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese