Socket Weld Elbow Fitting 90 Degree

8 USD ($)/Unit

Product Details:

- Connection Type Socket Weld

- Sealing Type Metal to Metal

- Temperature Range -20C to 220C

- Tolerance 0.03 mm

- Coating Type Uncoated

- Yield Strength 205 MPa min

- Diameter Matching Pipe Size

- Click to View more

X

Socket Weld Elbow Fitting 90 Degree Price And Quantity

- 8 USD ($)/Unit

- 10 Piece

- 8.00 - 15.00 USD ($)/Unit

- Carton Box / Wooden Case

- HRB 88 max

- Easy Socket Weld

- Excellent

- Forged

- Socket Weld Ends

- 7-10 Days

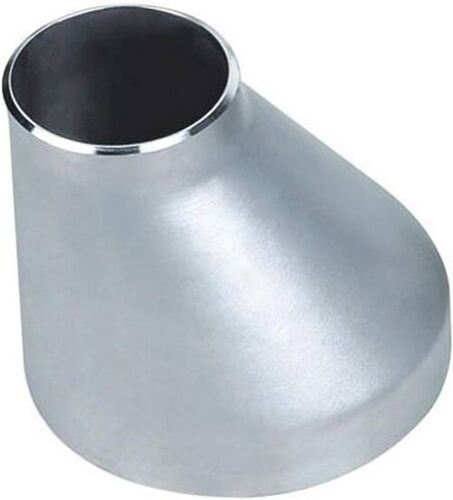

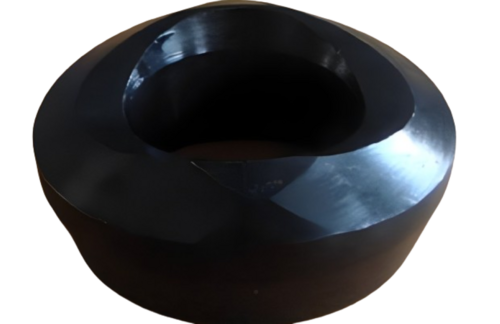

Socket Weld Elbow Fitting 90 Degree Product Specifications

- Matching Pipe Size

- 90 Degree Elbow

- 205 MPa min

- Round

- 1/2 inch to 4 inch

- Socket Weld

- Stainless Steel

- 304/316

- Uncoated

- Socket Weld Elbow Fitting 90 Degree

- Metal to Metal

- ASTM A182, ASME B16.11

- -20C to 220C

- 0.03 mm

- Socket Weld

- Rigid

- 3 mm

- Oil & Gas, Chemical, Power Plant, Water Supply

- Elbow

- 3000# / 6000#

- Polished

- Silver

- Pipe Fitting

- 515 MPa min

- Varies by size

- Carton Box / Wooden Case

- HRB 88 max

- Easy Socket Weld

- Excellent

- Forged

- Socket Weld Ends

- 7-10 Days

Socket Weld Elbow Fitting 90 Degree Trade Information

- Western Union, Letter of Credit (L/C)

- 1000 Piece Per Week

- 15 Days

- Yes

- Free samples are available

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- ISO 9001-2015,CE,FIEO,EEPC

Product Description

- Socket weld elbows have sockets on both ends, allowing them to be inserted into socket weld fittings and welded in place.

- They are used in high-pressure piping systems.

- Socket welds create sealed, leak-proof, high pressure pipeline configurations for the transporting of liquids or gases.

- Unlike butt welding, socket welds don't require any pre-weld machining, although the pipe ends should be clean in order to assure the integrity of the weld.

Superior Corrosion Resistance & Long-Term Durability

This 90 degree socket weld elbow boasts excellent corrosion resistance due to its stainless steel construction and polished surface treatment. Designed for use in harsh environments such as oil and gas, chemical, and power plant settings, it offers reliable performance and longevity, reducing the frequency of replacements and maintenance costs.

Precision Forging & Quality Assurance

Manufactured through a rigorous forging process, each elbow fitting adheres to strict ASTM and ASME standards. The high tensile and yield strengths, along with a tight tolerance of 0.03 mm, ensure dependable operation even under demanding pressures, providing peace of mind for engineers and installers alike.

Effortless Installation & Flexible Sizing

The socket weld design makes installation straightforward and secure for professionals working with pipe connections. With outer diameters ranging from 1/2 inch to 4 inch, the elbow fitting is versatile enough to suit a wide variety of piping systems, offering convenience and adaptability during setup.

FAQ's of Socket Weld Elbow Fitting 90 Degree:

Q: How is the Socket Weld Elbow Fitting 90 Degree installed in a piping system?

A: Installation is straightforward due to the socket weld ends. Pipes are inserted into the fitting and welded securely, ensuring a rigid and leak-proof metal-to-metal seal, ideal for high-pressure and corrosive environments.Q: What materials and standards are used for this elbow fitting?

A: The fitting is made from premium stainless steel grades 304 or 316. It is forged and polished, matching ASTM A182 and ASME B16.11 standards for consistent quality and strength in industrial applications.Q: Where can this 90 degree elbow fitting be used?

A: It is suitable for a range of industries, including oil and gas, chemical processing, power plants, and water supply systems, thanks to its corrosion resistance and robust design.Q: What level of corrosion resistance does the fitting offer?

A: Thanks to its high-quality stainless steel material and polished finish, the elbow fitting provides excellent resistance to corrosion, making it ideal for use in environments exposed to harsh chemicals or moisture.Q: What is the typical lead time for delivery and how is it packed?

A: The standard lead time is 7-10 days. Each fitting is securely packed in either a carton box or a wooden case to ensure safe handling and transportation during export.Q: What benefits does the forged manufacturing process provide?

A: Forging enhances the fitting's mechanical properties, improving tensile strength (minimum 515 MPa) and yield strength (minimum 205 MPa), while maintaining precise tolerances for reliable, long-term service.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Pipe Fittings' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese