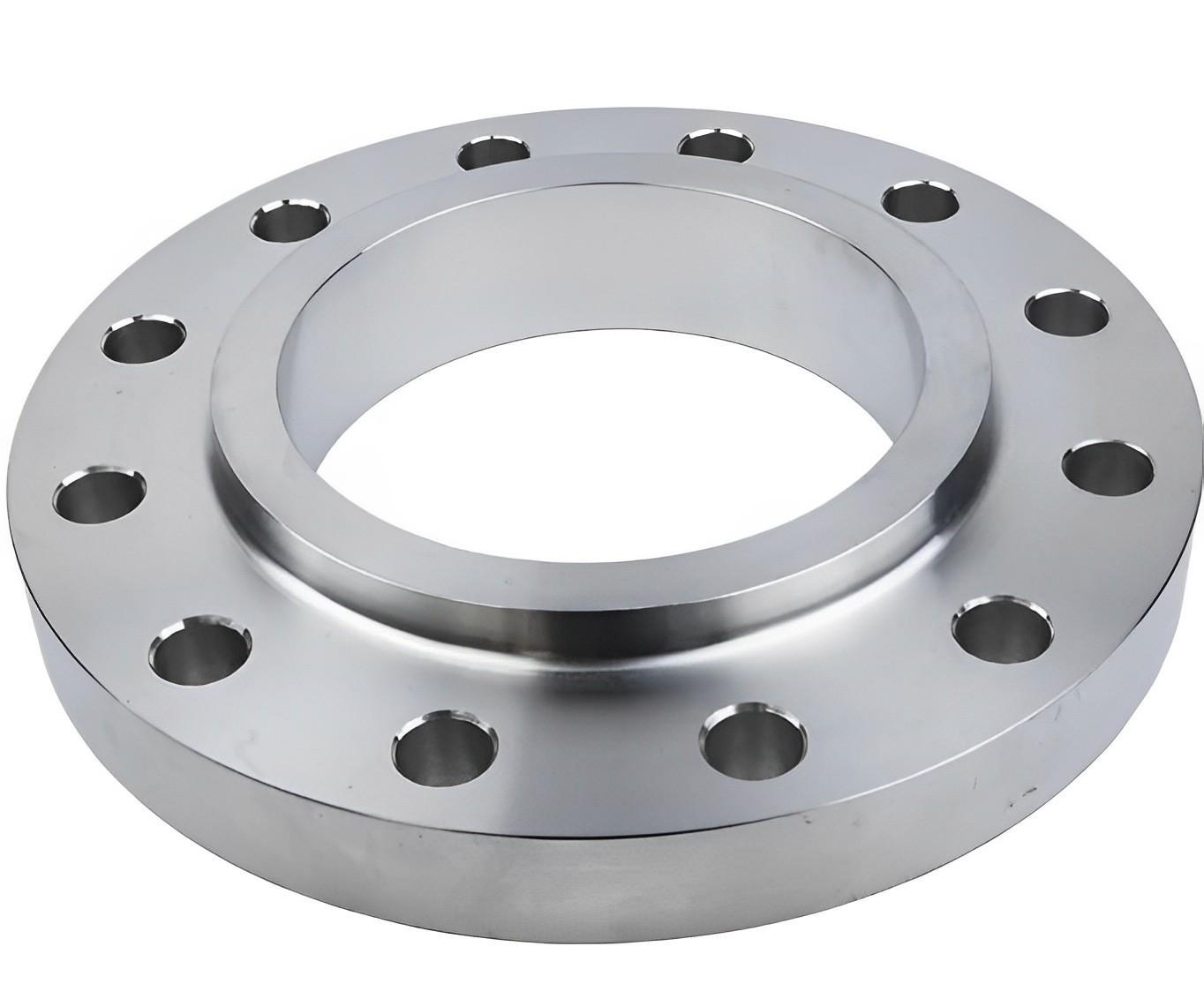

Stainless steel Socket Weld Flange SWRF 1/2 inch for Industrial

Product Details:

- Purity 99%

- Application Industrial Pipe Fitting

- Grade 304 / 316

- Dimension (L*W*H) 1/2 inch (Nominal Diameter)

- Feature Corrosion Resistant, High Strength, Leak Proof

- Product Type Socket Weld Flange (SWRF)

- Material Stainless Steel

- Click to View more

Stainless steel Socket Weld Flange SWRF 1/2 inch for Industrial Price And Quantity

- 1 USD ($)/Piece

- 1.00 - 10.00 USD ($)/Piece

- 50 Piece

Stainless steel Socket Weld Flange SWRF 1/2 inch for Industrial Product Specifications

- Stainless Steel

- Corrosion Resistant, High Strength, Leak Proof

- Class 150

- 1/2 inch (Nominal Diameter)

- 1/2 Inch

- Round

- 99%

- 304 / 316

- Industrial Pipe Fitting

- Polished

- Socket Weld Flange (SWRF)

- Silver

- Socket Weld

- Forged

- ASME B16.5 / ASTM A182

Stainless steel Socket Weld Flange SWRF 1/2 inch for Industrial Trade Information

- Any port in India

- 10000 Piece Per Month

- 10 Days

- Yes

- Free samples are available

- We, C-Way Engineering Exports give special attention to packaging. Due to longer transit time, machinery and goods are exposed to moisture and humid environment. We provide moisture proof packing and pack in strong wooden boxes. We provide pallets for easy loading and unloading of the goods. We ensure that the weight of the goods is evenly distributed.

Product Description

C-Way EngineeringExports is a leading supplier and exporters of Pipe Fittings. Our pipe fittingsare manufactured with precision and accuracy, using high quality raw materials.We offer all types of pipe fittings such as Elbows, Tees, Reducers, Unions,Couplings, Crosses, Caps, Swage Nipples, Plugs, Bushings, Adapters, Sockolet,Threadolet, Outlets and more.

Our Steel PipeFitting products are designed and manufactured with international qualitystandards ISO, ANSI, ASME, ASTM, BSP, DIN and NPT standard. Our Pipe Fittingsare durable and are ideal for multiple connections of pipes. Pipe Fittingsplays very important role in joining and connecting pipes, valves, flanges,pumps, compressor and alternative instrumentations to make a piping system. Weoffer different types of specifications, standards, sizes, dimensions, grades,wall thicknesses as per our client requirements.

Superior Strength and Leak-Proof Assurance

The SWRF 1/2 inch flange distinguishes itself with a hardness of 180-220 HB, ensuring robust performance in high-stress environments. Thanks to its leak-proof design and forged construction, it is able to sustain operating pressures typical in industrial pipelines, minimizing downtime and fluid loss.

Reliable Corrosion Resistance for Longevity

Manufactured from 304 or 316 stainless steel with a polished surface, this flange offers excellent resistance against corrosion, even when exposed to water, oil, gas, or steam. Its durability is further enhanced by compliance with ASTM A182, making it suitable for harsh industrial settings.

Easy Installation and Versatile Application

Featuring a socket weld end connection and round shape, this flange simplifies the installation process for pipe fitters. The 1/2 inch nominal diameter, precise bolt hole alignment, and compatibility with global standards ensure adaptability for a wide range of industrial systems.

FAQs of Stainless steel Socket Weld Flange SWRF 1/2 inch for Industrial:

Q: How is the Stainless Steel Socket Weld Flange SWRF 1/2 inch installed in a pipeline?

A: This flange is installed by inserting the pipe into the socket end and welding around the joint, providing a strong and leak-proof connection suitable for high-pressure industrial systems.Q: What benefits does the raised face (RF) design offer in this flange?

A: The raised face enhances sealing capability between the flange and gasket, improving leak resistance under pressure and making it ideal for processing water, oil, gas, and steam.Q: When should you choose grade 304 versus 316 stainless steel for your application?

A: Grade 304 is suitable for general use and offers good corrosion resistance. Grade 316, with added molybdenum, is recommended for more corrosive environments, such as chemical processing or marine applications.Q: Where can this flange be utilized within industrial operations?

A: It is commonly used in chemical plants, oil refineries, water treatment facilities, and steam distribution systems, providing secure and durable pipe connections.Q: What process ensures the flanges durability and high performance?

A: The flange is forged, a process that increases its mechanical strength, refines its grain structure, and ensures consistent hardness (180-220 HB) for longevity.Q: How does the flange maintain leak-proof joints even at high temperatures?

A: The combination of the raised face, socket weld design, and precise manufacturing to ASME B16.5 standards allows the flange to create highly reliable, leak-proof connections from -20C to 550C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese